CASE FILE ENTRY // MATERIAL FAILURE LOG

Every defect has a story.

These case studies are fictionalized representations of real challenges I encountered in high-precision forging environments. Under the guidance of corporate metallurgists and NDT technicians, I traced failures back to their roots—investigating metallurgical issues like voids, porosity, and inclusions—and evaluated non-destructive testing methods and process flow.

Each reconstruction reflects how I approached failure analysis from the ground up, turning anomalies into actionable engineering insight, while protecting confidential data under NDA through abstracted technical storytelling.

🧩 Subsurface Void Investigation – Aluminum Alloy

Objective: Investigate dimensional shifts observed during machining; metallographic analysis revealed a subsurface void near the material boundary.

Material: Aluminum alloy (simulated for demonstration purposes)

Methodology: Cross-sectioned the sample, followed by metallographic polishing and 20x objective lens inspection.

Findings:

- 🕳️ Identified a void approximately 0.0004 in in diameter.

- 📍 Located near the outer boundary—suggesting origin during casting or rolling stages.

Outcome: Findings were used to revise process control parameters for billet manufacturing to prevent future defects.

🧪 Metallographic Simulations — Aluminum Alloy

🟤 Subsurface Void Investigation — Aluminum Alloy

- Objective: Investigate machining shifts; voids found near the material boundary.

- Material: Aluminum alloy (simulated)

- Methodology: Cross-sectioned, polished, and examined under 20x lens

Findings:

- Void approx. 0.0004 in wide

- Located near outer edge — likely formed during casting or rolling

Outcome: Helped adjust process control parameters for billet manufacturing.

Void width ≈ 0.0004 in | 20x objective lens

⚪ Simulated Metallographic Analysis — Hydrogen Porosity

This simulated aluminum sample shows a rounded void near the boundary, consistent with hydrogen porosity.

- Magnification: 20x objective lens

- Void diameter: ~0.0006 in

- Observation: Typical of gas entrapment during solidification

Porosity width ≈ 0.0006 in | 20x objective lens

🧪 This example is for educational use only and does not reflect proprietary data.

🧫 Simulated Gas Void — Alternate Morphology

This simulation represents a variation in hydrogen or gas porosity, featuring a more elongated or asymmetrical internal void — a pattern sometimes seen in solidification shrinkage or entrapped gas migration during cooling.

- Magnification: 20x objective lens

- Void type: Elongated/collapsed bubble morphology

- Use case: Failure analysis or process QA

Void feature | 20x objective lens

🧪 This micrograph is a simulation for educational and display purposes only.

⚠️ All visuals are fictionalized simulations and are NDA-safe educational content.

💻 Corrosion Comparison Dashboard

⚫ Pitting Corrosion — 6261-T6 Aluminum

Localized corrosion initiating at microstructural transitions in heat-treated aluminum alloys.

📝 Pit size: 41.2 µm × 16.6 µm

🔍 Key cue: Irregular, isolated pit with clean matrix around it

- Magnification: 20x

- Common location: Grain boundaries and heat-affected zones

This is a simulated micrograph. Educational use only.

🟠 Surface Corrosion — 304 Stainless Steel

Uniform corrosion degrading the surface evenly over time.

📏 Depth: ~54.9 µm

🌊 Profile: Shallow, smooth, widespread etching

- Magnification: 20x

- Cause: Breakdown of chromium-rich oxide layer

Represents typical stainless degradation seen in industrial or outdoor environments.

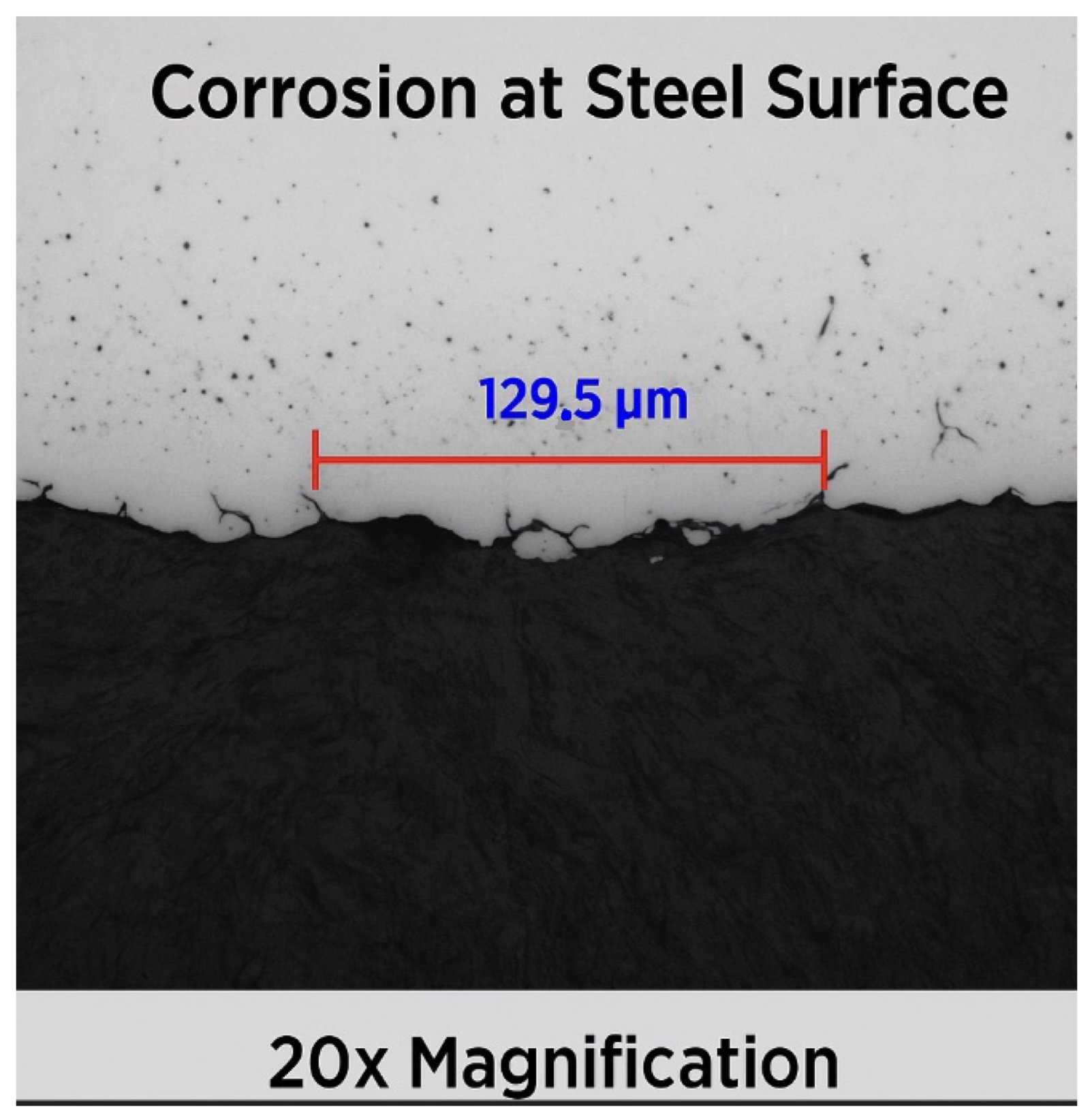

🔵 Advanced Surface Attack — Steel Alloy

Severe corrosion progressing into material with jagged morphology.

📏 Width: ~129.5 µm

⚠️ Visual cue: Uneven edges, aggressive front

- Magnification: 20x

- Cause: Coating failure + mechanical stress + electrolyte entrapment

High-risk failure pattern in structural steel—requires early detection and barrier reinforcement.

📊 Quick Comparison Table

| Material | Corrosion Type | Depth / Width | Visual Cue | Severity |

|---|---|---|---|---|

| 6261-T6 Aluminum | Pitting Corrosion | ~41 µm x 17 µm | Isolated irregular pits | ⚠️ Medium |

| 304 Stainless Steel | Surface Corrosion | ~54.9 µm | Smooth, shallow etch | ⚠️ Low |

| Steel Alloy | Advanced Surface Attack | ~129.5 µm | Jagged edges, trenching | 🚨 High |

Data is representative of simulated metallography. For technical visualization only.

🔬 Alpha Case in Titanium – Root Cause & Visuals

Alpha case is a brittle, oxygen-enriched surface layer found in titanium alloys after high-temperature exposure. It must be minimized in aerospace and critical applications.

- Material: Ti-6Al-4V

- Cause: Overheating due to equipment failure and double striking

- Observed Thickness: ~0.0016 in

- Issue Timeline: Strike Event (8/26/24) → Heater Malfunction (9/9/24)

Preventive Measures:

- Real-time thermocouples on dies and slugs

- Vacuum or argon-shielded heat treatment

- Post-process removal via grinding or chemical milling

Simulated metallographic inspection for demonstration. Based on WO640358 internal review data.

🧪 Test Method Overview

Samples were prepared through standard metallographic polishing techniques and inspected using a 20x objective lens. These visuals are reconstructed simulations based on typical alpha case behavior in titanium forgings.

- Cross-sectioned post-forge billets (Ti-6Al-4V)

- Polished with 600–1200 grit, then etched

- Captured under LED illumination and scaled

These simulations are NDA-compliant and built to illustrate failure logic, not specific data.

🛠️ Alpha Case Prevention Tips

- ✅ Ensure full argon shielding or vacuum heating

- ✅ Avoid thermal overshoot by monitoring induction frequency

- ✅ Remove case post-forge with light grinding or chemical etching

- ✅ Avoid dry hits during setup – this accelerates oxidation

Note: Alpha case is common but must stay under 0.0015–0.0020 in for aerospace applications.

⚖️ Alpha Case vs. Pitting — Key Differences

| Trait | Alpha Case | Pitting |

|---|---|---|

| Location | Outer oxidized rim | Local surface voids |

| Cause | Oxygen diffusion during heating | Gas entrapment, stress, or contamination |

| Visual Cue | Discolored band, no cavity | Sharp-edged pit or void |

| Fix | Grind/etch + improve shielding | Improve melt quality or inspection |