Case Files: Material Failure Notes

NDA-safe examples • simulated micrographs • process diagnostics

Concise case records of metallurgical issues—voids, porosity, cracking—observed in aerospace-grade forging contexts. Entries prioritize mechanism, evidence, and corrective actions.

Metallographic Simulations — Aluminum Alloy

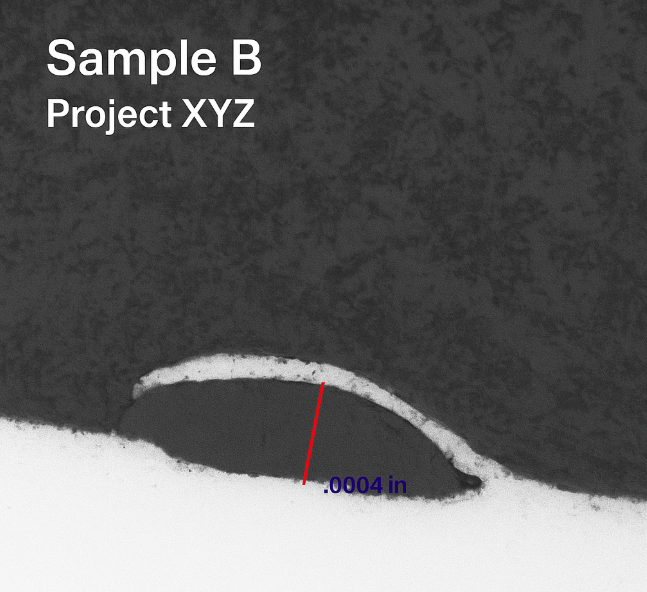

Subsurface Void — Edge Defect

- Material: Aluminum alloy (simulated)

- Inspection: Cross-section, polish, 20× objective

- Dimension: ≈ 0.0004 in

- Likely mechanism: casting/rolling porosity at edge

Edge-localized voids disrupt tool engagement and dimensional control; early detection informs upstream process adjustments.

Hydrogen Porosity — Spherical Void

Typical of moisture-driven entrapment during solidification. Small but impactful on fatigue life for flight-critical parts.

Elongated Gas Void — Collapsed Morphology

Asymmetric collapse intensifies local stress—often a product of rapid cooling or insufficient gas dispersion.

Simulated reference cases — NDA-safe visuals.

Corrosion & Surface Attack — Quick Reference

Pitting — 6261-T6 Aluminum

Cue: isolated elliptical pit with dark rim near boundary transitions.

Cause: chloride ingress + poor passivation + thermal cycling.

Uniform Surface Attack — 304 Stainless

Cue: matte grain etch; even thinning.

Driver: humidity exposure and oxide breakdown.

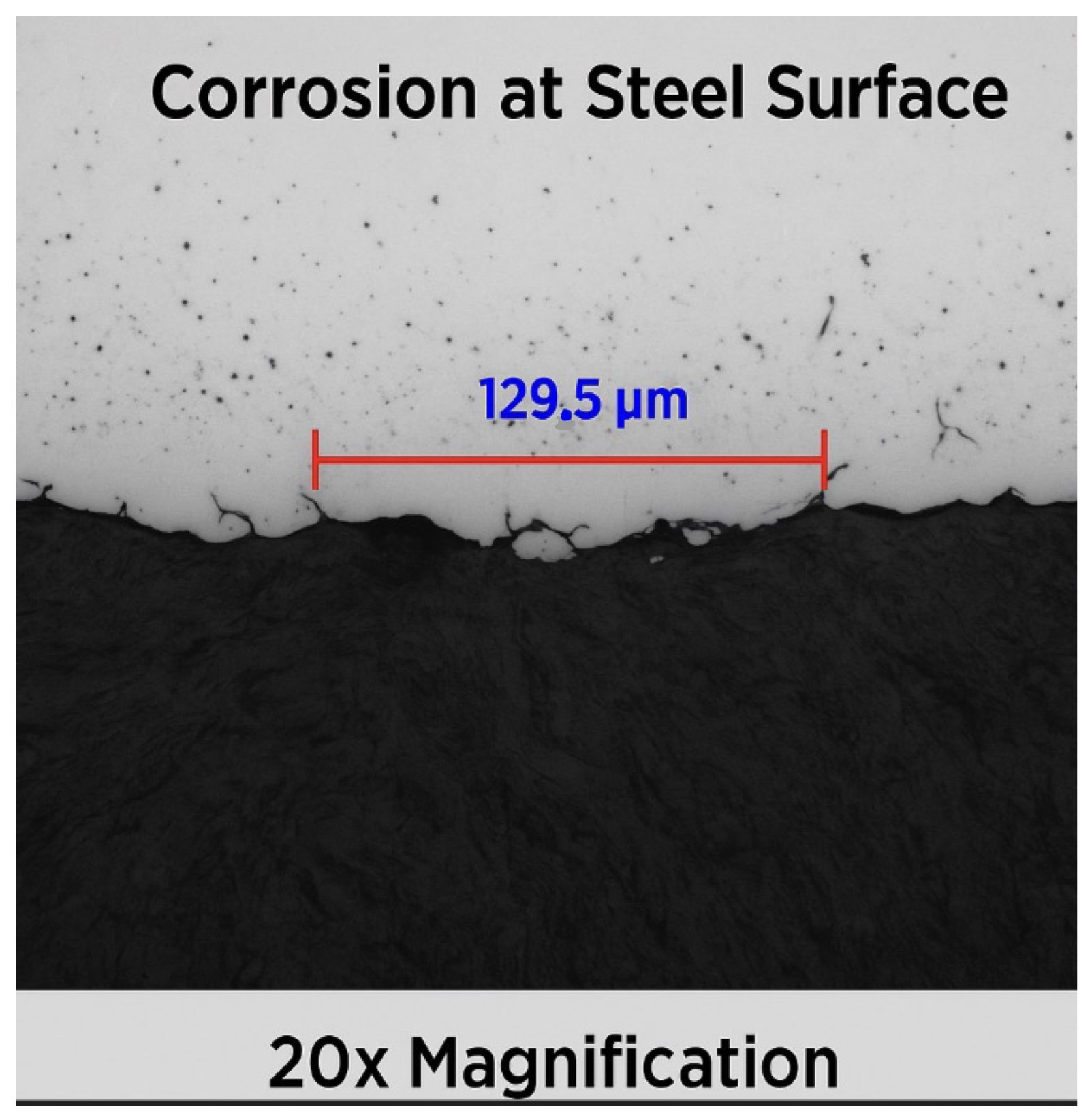

Advanced Trench Attack — Steel Alloy

Jagged, multi-grain loss driven by coating failure + stress + electrolyte pooling.

Galvanic Corrosion — Bimetal Joint

Pair: Aluminum fastener (anodic) + stainless washer (cathodic). Moisture creates an electrolyte bridge; halo forms at the anodic interface.

Hydrogen Embrittlement — High-Strength Steel

Atomic hydrogen ingress + tensile stress → delayed brittle cracking. Common after acid cleaning or plating.

| Material | Mode | Depth / Risk | Visual cue | Primary driver |

|---|---|---|---|---|

| 6261-T6 Al | Pitting | 41.2×16.6 µm | Isolated elliptical pit | Cl⁻ ingress + cycling |

| 304 S.S. | Uniform attack | ~54.9 µm | Matte grain etch | Humidity / oxide loss |

| Steel | Trench attack | ~129.5 µm | Jagged trench | Stress + coating failure |

| Al/Stl joint | Galvanic | Variable | Halo at fastener | Potential mismatch |

| HSS | Embrittlement | Crack growth | Brittle subsurface | H uptake + stress |

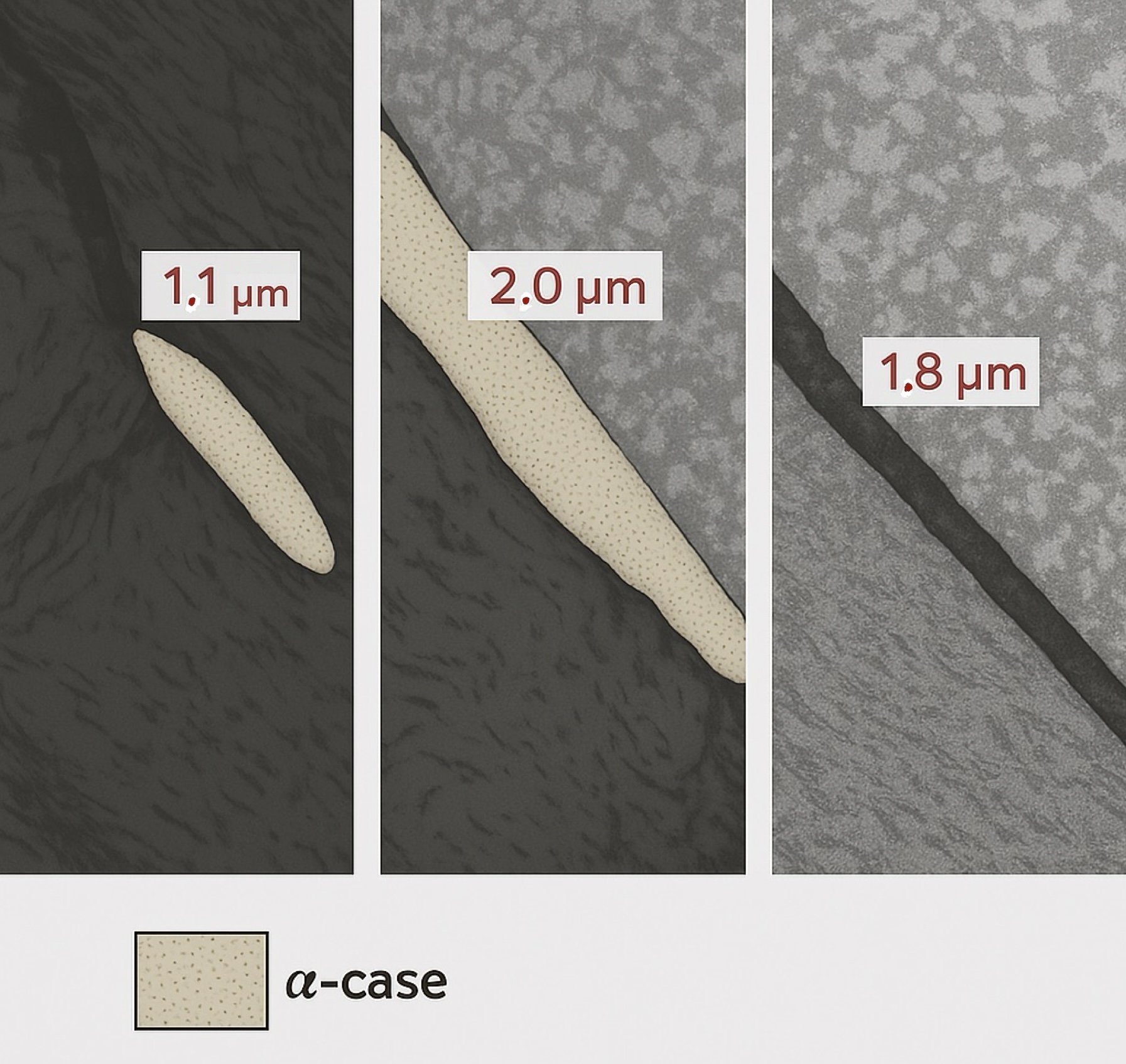

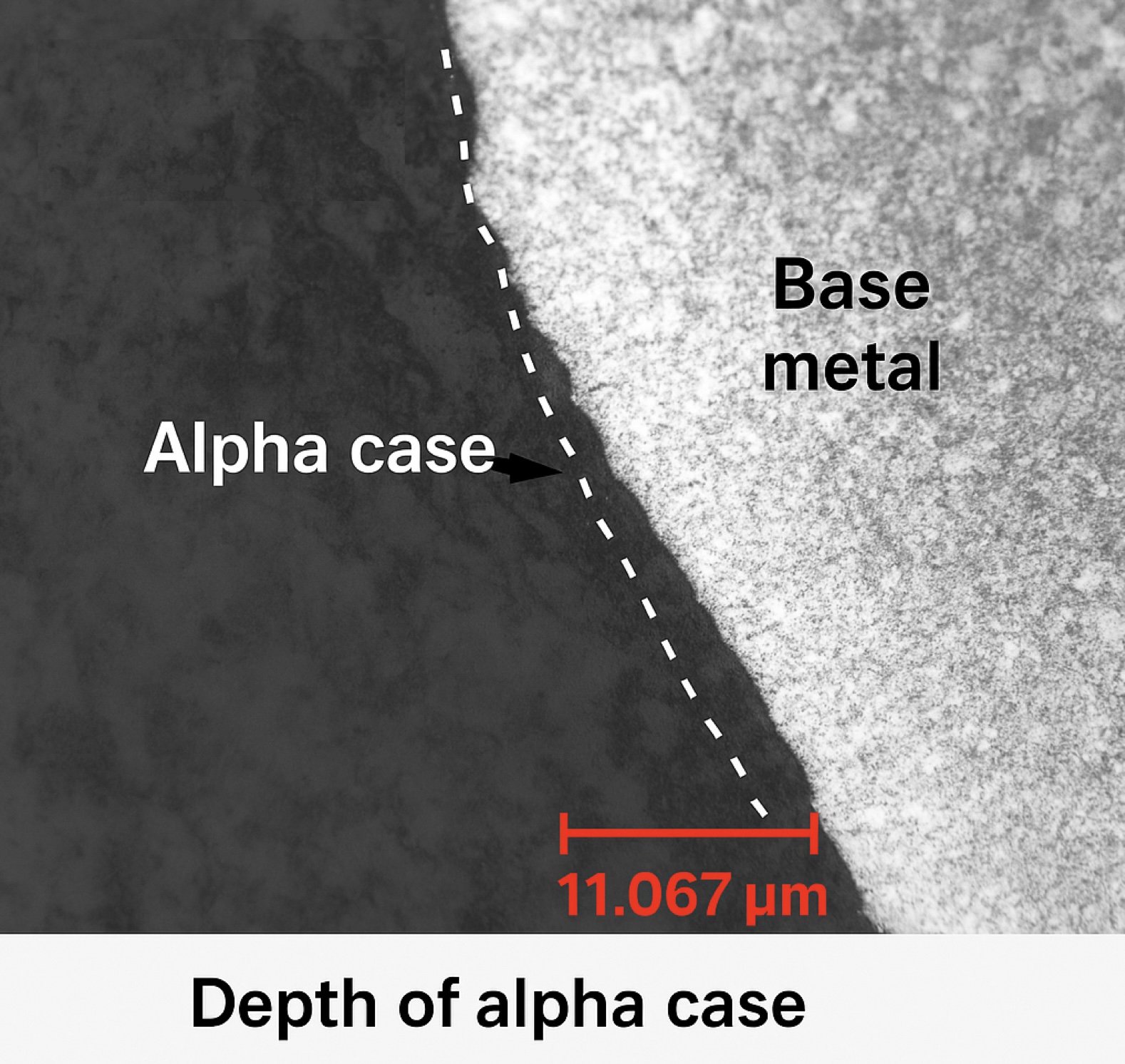

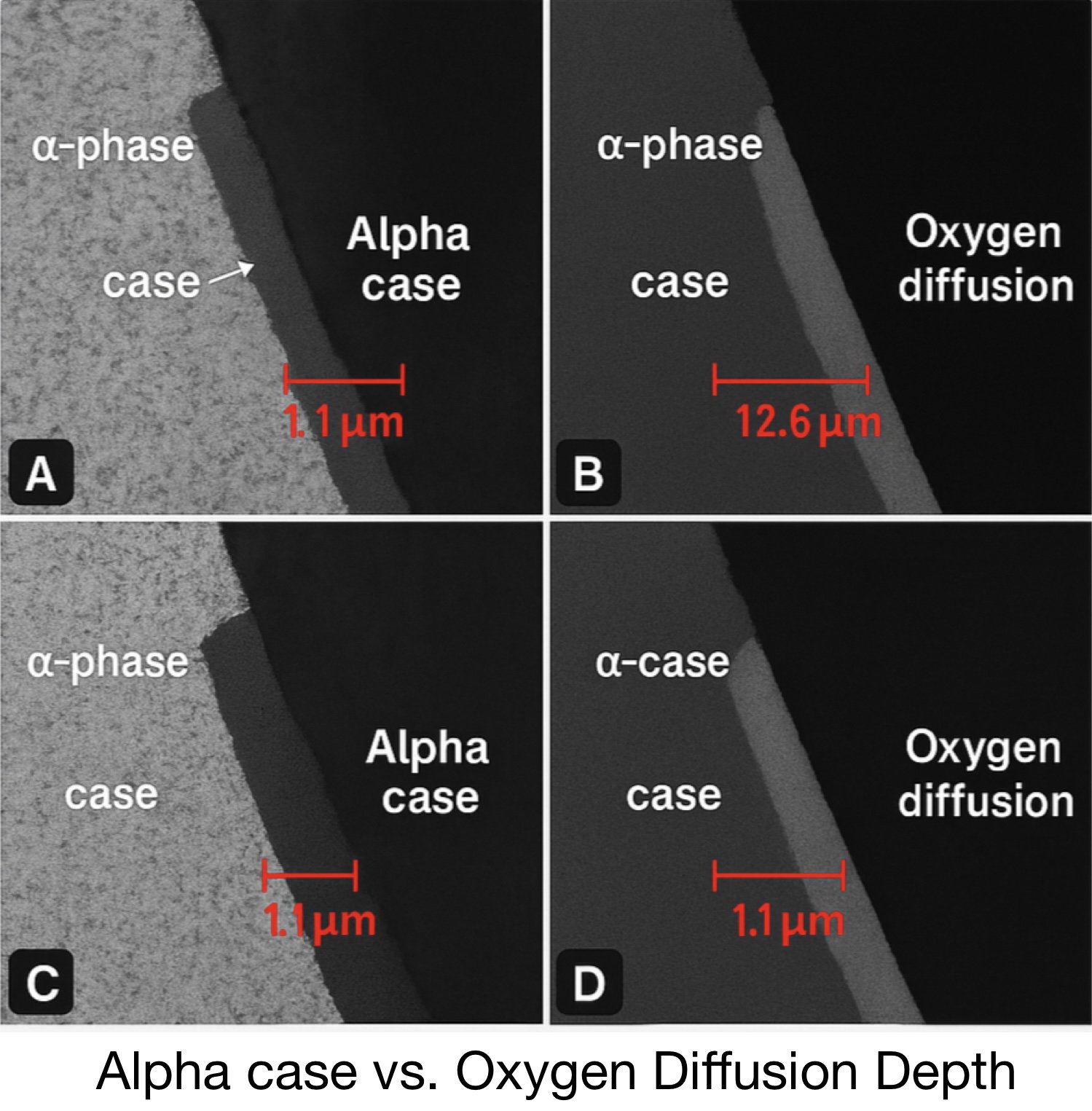

Alpha Case in Titanium — Notes & Figures

Oxygen-enriched surface layer formed at high temperature. Impact: reduced ductility and fatigue life. Acceptability depends on depth, location, and part criticality.

Fig. 1 — Near-surface alpha case (~2.0 µm)

Fig. 2 — Deeper progression; variable shielding

Fig. 3 — Faint rim; controlled condition

Fig. 4 — Depth variability across surface (1.1–12.6 µm)

Fig. 5 — Upper limit (~0.002")