Manufacturing Defects & Failure Modes

Representative microstructural examples used to identify defect morphology, scale, and likely formation mechanisms in forging and high-temperature processing. Focus is on root-cause reasoning and engineering-relevant interpretation.

How I Frame a Case

A repeatable structure for identifying what a defect is, why it forms, and what actions are technically justified.

1) Define

Morphology, location, and scale.

2) Hypothesize

Likely process, material, or environmental drivers.

3) Verify

Targeted checks to confirm or eliminate causes.

4) Mitigate

Controls, rework options, and prevention strategy.

Hydrogen-Induced Subsurface Porosity — Aluminum

Subsurface blister/void morphology consistent with gas porosity that can remain hidden until machining or thermal cycling.

Mechanism

Trapped hydrogen → internal void growth → blistering / breakout risk.

Engineering impact

Fatigue knockdown + late-stage scrap / rework exposure.

Localized Pitting — Aluminum Alloy

Discrete pit morphology used for signature recognition and scale. Often associated with passive film breakdown, inclusions, or aggressive environments.

Mechanism

Passive film breakdown → localized attack → pit growth.

Engineering impact

Stress concentration + crack initiation susceptibility.

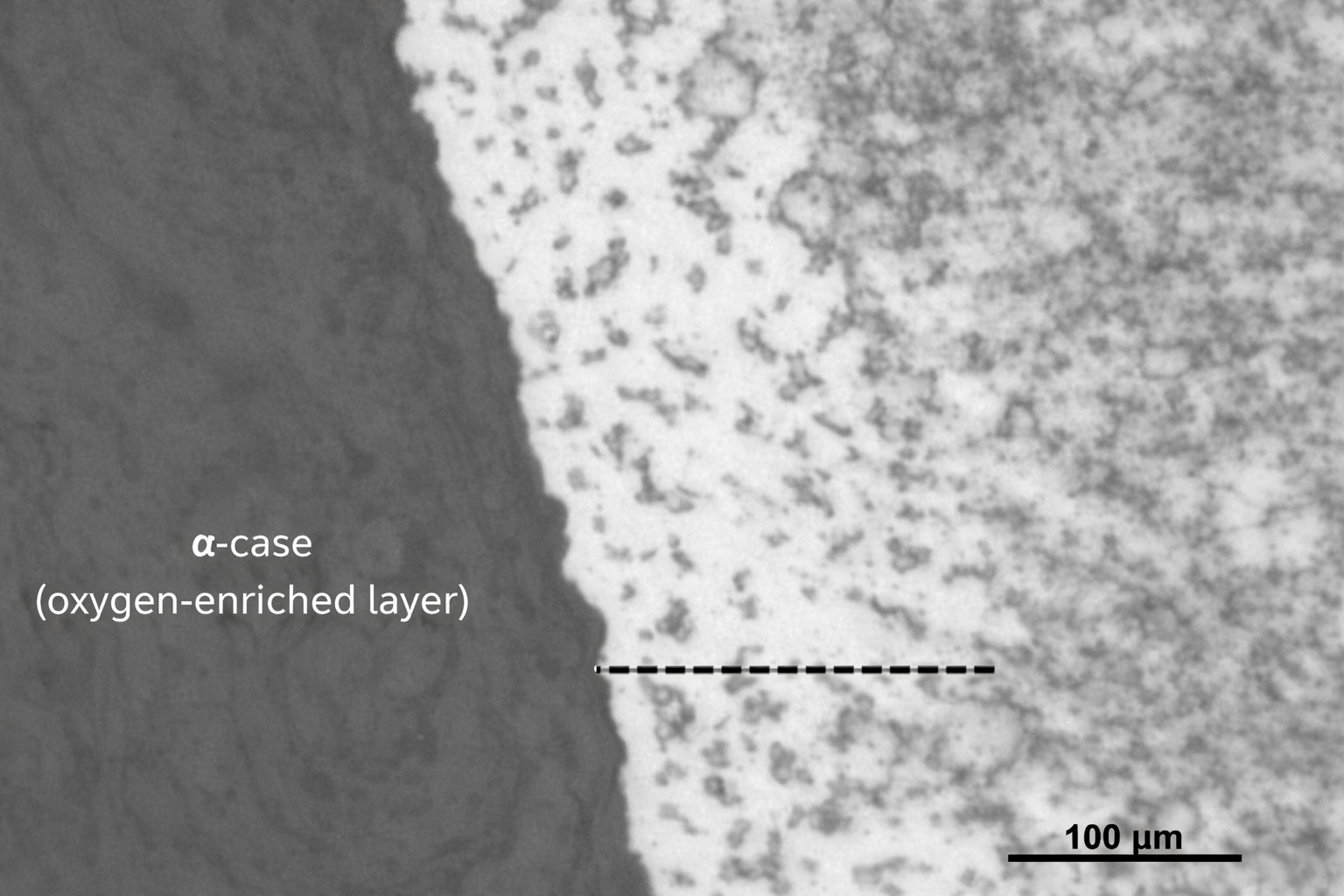

α-Case Formation — Titanium

Oxygen-enriched surface layer formed during high-temperature exposure. A known embrittling condition if not removed post-process.

Mechanism

Oxygen diffusion at temperature → α-stabilized surface zone.

Engineering impact

Embrittlement + fatigue performance risk if retained.

Corrosion Damage — 304 Stainless Steel

Cross-sectional corrosion damage used as a morphology reference for section loss vs. localized pitting signatures.

Mechanism

Localized attack / interface degradation in an aggressive environment.

Engineering impact

Wall thinning + surface integrity and durability concerns.

Images and descriptions are representative examples used for failure-mode recognition and discussion.