Robotics • Embedded Control • Prototyping

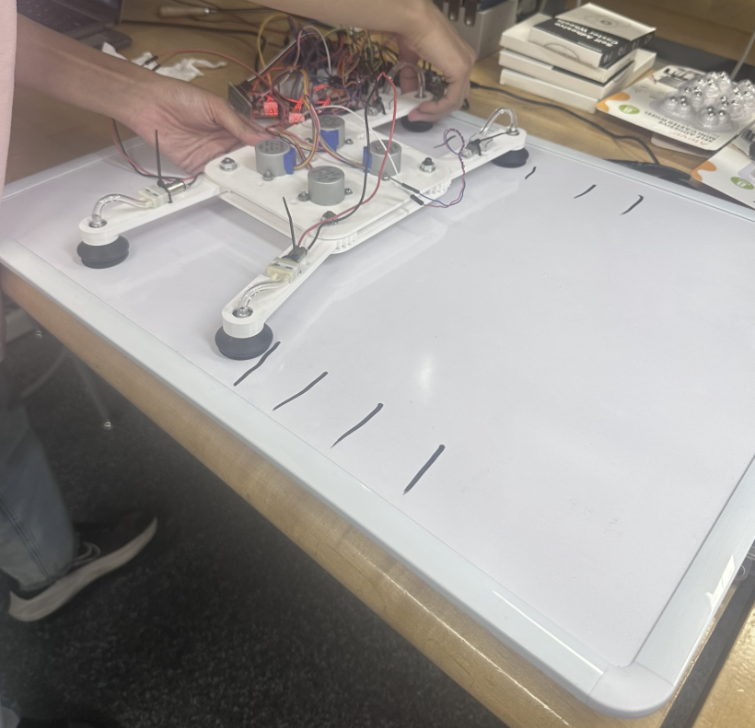

Suction-Based Quadruped Robot

Early-stage four-legged suction climber integrating 3D-printed legs, stepper-driven arms, and mini vacuum pumps controlled via Arduino Mega. Built and tested as a team project in ME225, with my contributions focused on the suction and release subsystem, power distribution, and bench-level debugging when real component behavior differed from datasheets.

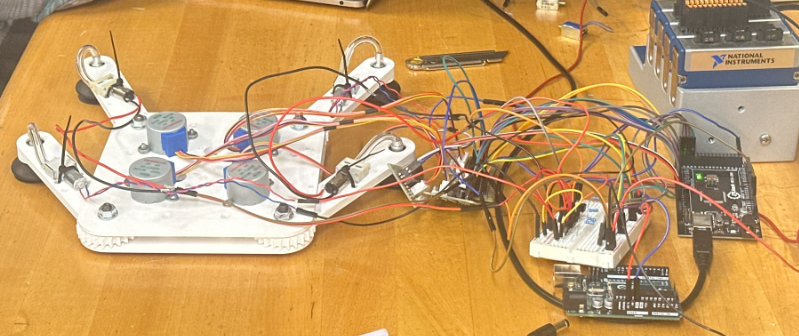

Arduino Mega

28BYJ-48 Steppers

Mini Vacuum Pumps

Solenoid Release Valve

Power Distribution

Bench Debugging

System Overview

- Locomotion concept: alternating suction attachment and release while stepping arms reposition the body.

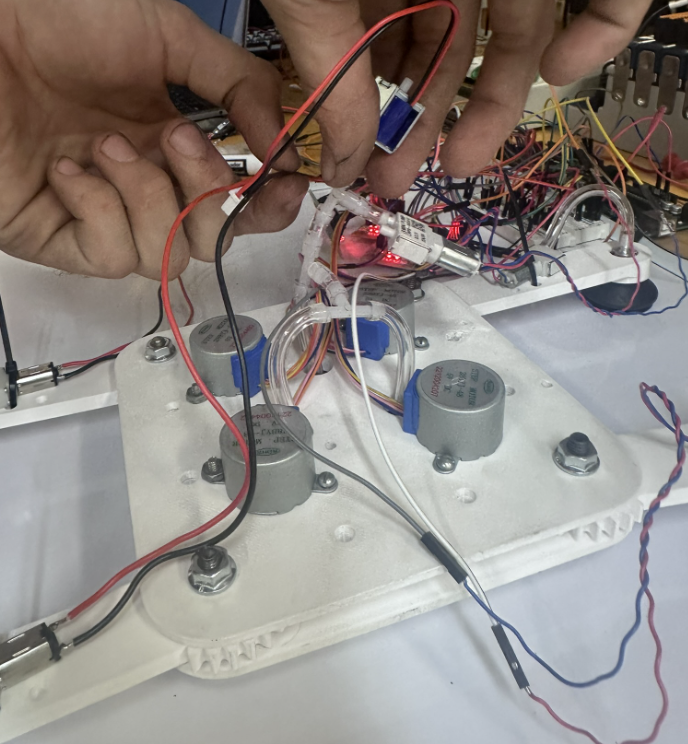

- Actuation: stepper motors drive arm motion; each foot uses a dedicated mini vacuum pump for adhesion.

- Control: Arduino Mega sequencing for attachment, detachment, and movement.

Electrical & Power

- 5 V rail supplying stepper motors (~1.5 A observed during transitions).

- 3.3 V rail supplying pumps (~640 mA total observed) plus solenoid actuation (~0.33 A).

- Bench verification using multimeter checks for voltage stability, current draw, and noise during attach/release.

What I Did

- Sourced suction hardware and implemented a solenoid-based vent/release method to break vacuum on command.

- Integrated wiring and power distribution; validated 3.3 V and 5 V rails under real load conditions.

- Observed uneven release timing across legs and iterated on sequencing and airflow paths during testing.

Key Technical Challenges

- Suction release inconsistency driven by airflow path sensitivity and leakage.

- Non-uniform vacuum distribution causing one leg to lag during release.

- Pump and motor transitions introducing voltage sag and noise; wiring and pump configuration changes provided partial improvement.

Build Log

Additional prototype-stage photos included for system context without overstating ownership of the full mechanical design.

Future Improvements

- Standardize suction line routing so each leg sees similar flow resistance and release timing.

- Refine vent and valve placement to make detachment repeatable across surfaces.

- Improve power delivery and regulation to reduce voltage sag during transitions.

- Add simple vacuum or pressure feedback per foot to confirm attachment and flag stuck legs.

Potential next step: quick power and thermal budget covering pump draw, driver losses, and regulator dissipation.